Structural Steel vs. Engineered Beams

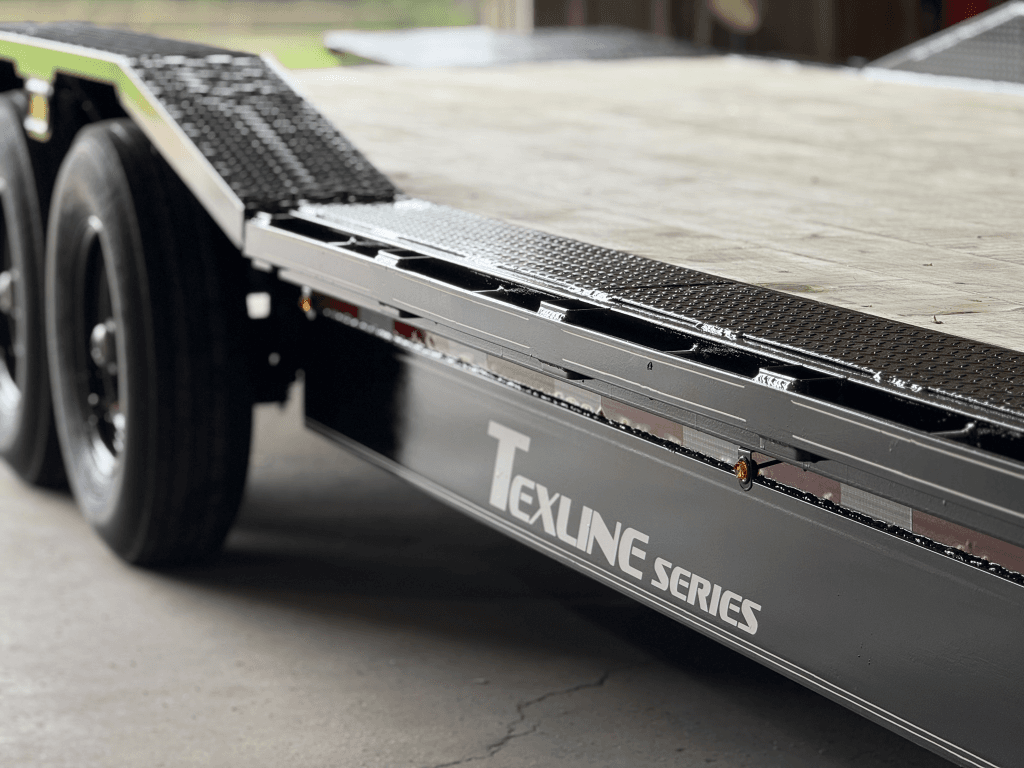

Why Texline Trailers Uses Hot-Rolled Structural Steel

Not All Innovation Is an Upgrade

As the trailer industry continues to evolve, more manufacturers are turning to lightweight, engineered structural components in an effort to reduce trailer weight and increase payload capacity. On paper, it sounds like a smart move. But at Texline, we’ve taken a step back to ask a more fundamental question:

What are we gaining, and what are we giving up?

That question has only strengthened our long-standing commitment to building trailers with hot rolled structural steel. For more than 40 years, we’ve prioritized strength, durability, and real world performance over trends — and we stand by that approach today.

Understanding the Difference: Structural vs. Engineered Beams

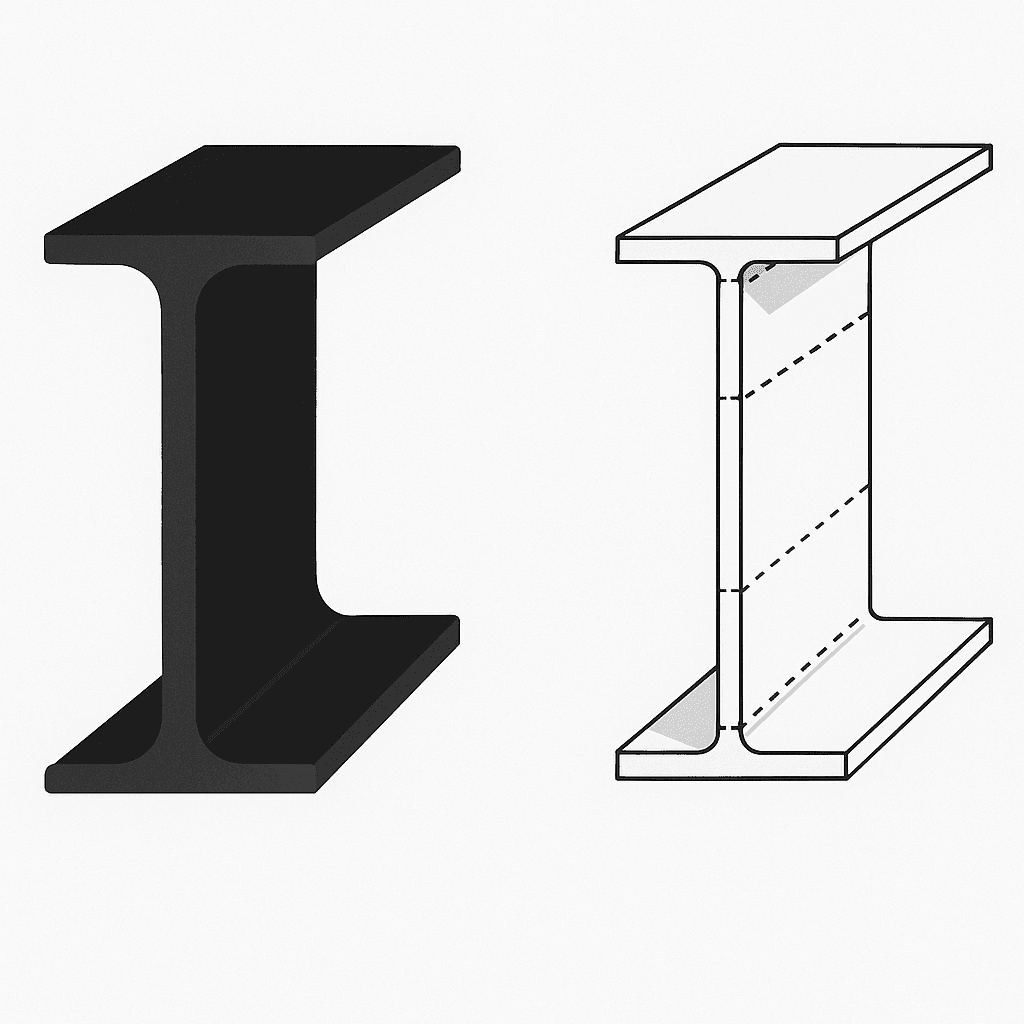

“Engineered” I-beams and channels are typically fabricated by welding thinner flat plate or strip steel into a structural shape. This process allows manufacturers to use less material, reduce weight, and optimize steel placement for specific load conditions. These fabricated beams may perform well in controlled environments or meet minimum structural requirements — but that doesn’t mean they’re built to handle years of rough use, uneven loads, or off-road conditions.

In contrast, hot-rolled structural beams are formed in a steel mill under extreme heat and pressure. They are one-piece, solid steel members with a continuous grain structure, free from weld seams or stress points introduced by fabrication. They are heavier, yes — but also far more

robust where it counts.

The Texline Standard: Overbuilt by Design

Texline trailers are built with hot-rolled structural I-beams and channels in all critical areas — mainframes, goosenecks, crossmembers, and more. Here’s why:

- Torsional Strength: Solid structural members resist twisting and flexing better than

fabricated alternatives, especially under off-axis or uneven loads. - Weld Integrity: A solid beam offers stronger, more reliable weld points without the risks

of heat-affected zones or seam failure. - Fatigue Resistance: Hot-rolled steel holds up better over time, particularly in high-stress

applications like heavy haul, construction, and off-road transport.

In short: our trailers aren’t just built to meet spec. They’re built to exceed expectations — year after year, mile after mile.

Why It Matters

We understand that every pound matters. Reducing frame weight can technically increase payload. But it also means you’re operating with less margin for the unexpected: potholes, off road use, load shift, or years of wear and tear.

At Texline, we don’t build trailers for controlled lab conditions — we build for real life. That’s why we’ve made the deliberate decision not to adopt engineered beam construction. It simply doesn’t align with our values or the performance standards our customers have come to expect.

Yes, our way costs more. And yes, it adds weight. But that’s the price of peace of mind — for our customers and for the legacy we’ve built.